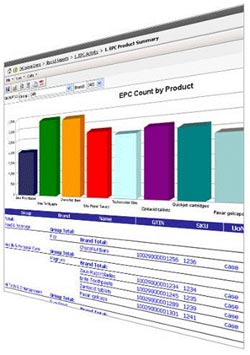

Real-Time Reporting and Alerts

OAT’s Asset Tracking and Work-in-Process solutions provide unmatched insights through a wide range of reports, including:

- EPC

movements

- product summaries

- site-to-site movement analysis

- track

and trace

- track

and trace

- Interactive

timeline reports

- dwell time by product

- route times

- week-to-week trends

- Logistics

reports

- shipment receiving

- order receiving

- exception analysis

- Inventory

reports

- product flow and availability

- WIP

- finished goods

- Asset reports

- utilization

- uptime/downtime

- location

- RFID

performance

- read rates by read point

As materials move

from facility to facility, key components,

tools and completed orders are more

likely to be misplaced, creating manufacturing

choke points and dissatisfied customers.

With real-time alerts, sent directly

to a handheld reader, web browser or

stack light, manufacturers are notified

immediately when:

As materials move

from facility to facility, key components,

tools and completed orders are more

likely to be misplaced, creating manufacturing

choke points and dissatisfied customers.

With real-time alerts, sent directly

to a handheld reader, web browser or

stack light, manufacturers are notified

immediately when:

- a process step is missed

- an order is mis-shipped

- an asset is moved to the wrong facility

- asset contents are due to expire

All alerts are configurable to mirror specific business processes.

"Most supply

chains are riddled with blind spots.

Most service parts supply chains

don’t react to a problem

until it hits the customer—and

by then it’s too late. Spotting

problems sooner makes them easier

to avoid. And leaves you with many

more options."

– Deloitte & Touche USA

Manufacturing Practice

OAT Foundation Suite

OAT Foundation Suite